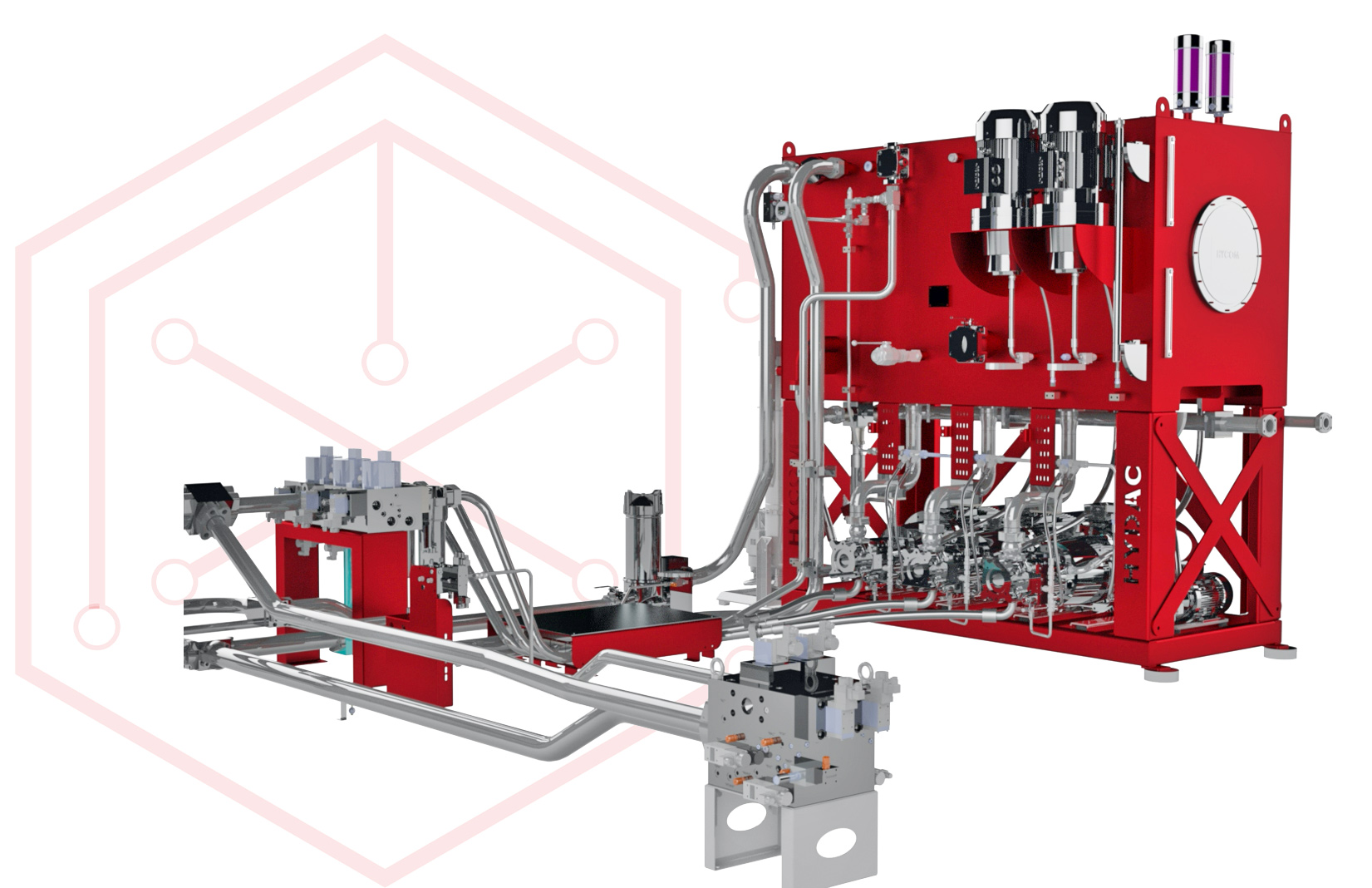

The test bench, located on the HYDAC site in Apeldoorn – The Netherlands, is used for testing and adjusting hydraulic components, manifolds and cylinders, among other things. Click on the parts for an image of the applied HYDAC sensors and components. Also view the “easy start-up” to start predictive maintenance at your own location.

Error: Contact form not found.